.png)

Kipsta's headquarters in Tourcoing, just north-east of Lille, France, is something like the footballing version of Willy Wonka's 'Chocolate Factory'.

The 'Kipstadium' spans over 45,000m squared, has 20 indoor and outdoor courts and pitches and a 900 metres squared Kipsta store.

The general public, schools and professional and amateur sports teams are able to use the facilities.

Advert

But the space, built on an old industrial site, is much more than a sports complex. It serves as the design hub of Kipsta, Decathlon's football brand, as they try and make waves in the football game.

Kipsta have the goal of being the world leader on balls and are in a good place to do so given they are the official suppliers for Ligue One, where Lionel Messi, Kylian Mbappe and Neymar strut their stuff weekly.

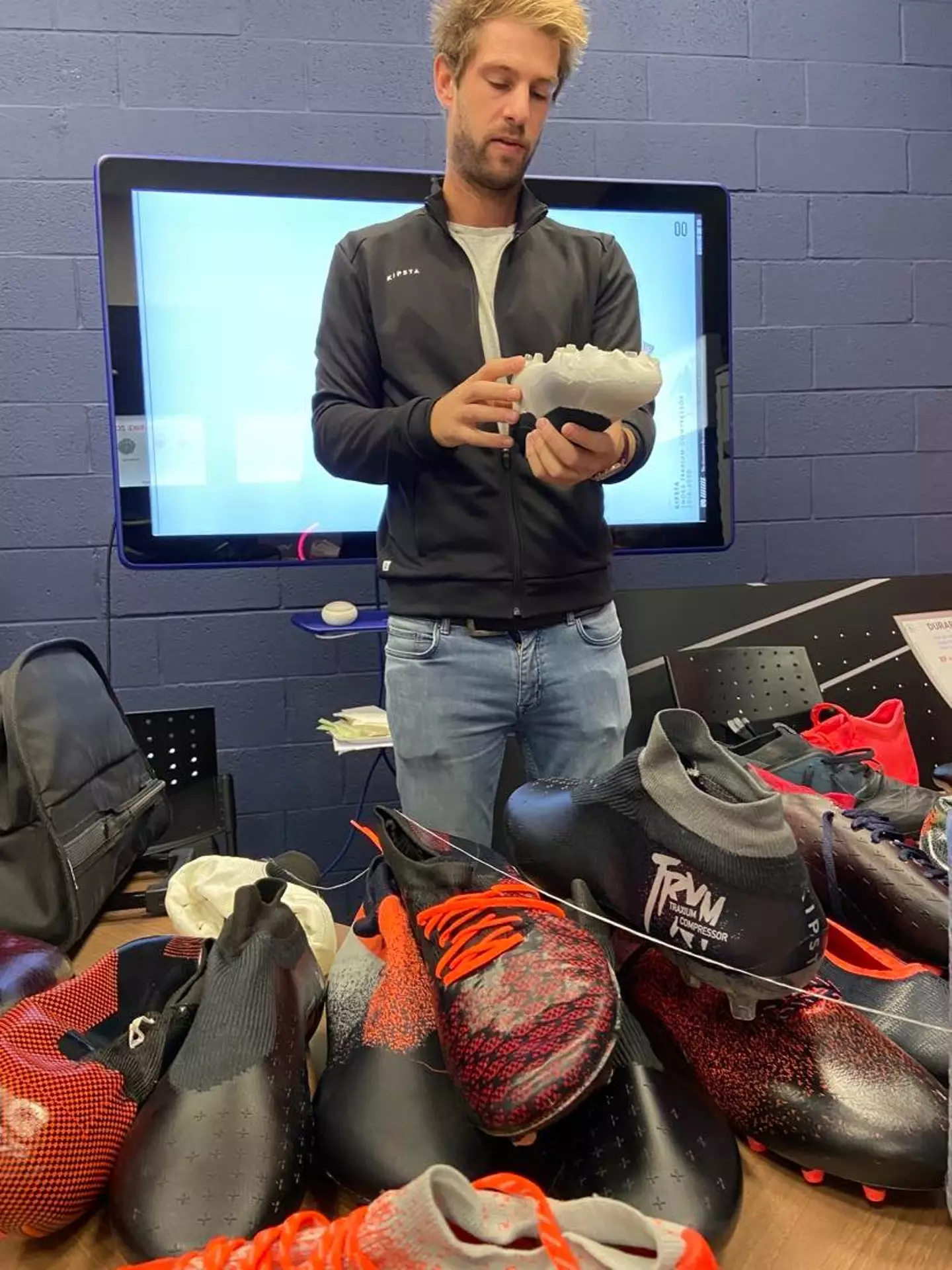

But they are also desperate to become the the third major player when it comes to boots, rivalling giants like Nike and Adidas.

They pride themselves on price and value, with products that are "technical, durable and accessible".

And those three words would provide the perfect summary of their latest release, the 'Traxium Compressor', which promises to be a game-changer in the market.

Priding themselves on their technology and being a specialist in the game, Kipsta say this is the "biggest innovation in the football boots market" and have spent a total of four years developing a brand new way to make the cleats, which cost £119.99.

The jet black boots are laceless but solid inside, with the eco friendly outsole made from defective products returned placed outsole inside three socks with no split.

Optimal comfort is provided with foam pads.

They were made from two socks, with the polyester thread heated at temperature of 140 to 150 degrees to become transparent in a totally different process of thermocompression, heat and pressure.

It's a 15 minutes mold for one pair of boots but the overall project saw the socks knitted in Istanbul, Turkey, with threads from Asia and then the compression take place in Nantes.

The final touches were completed in Paris, with the sticker going on to finish the job. The finished goods supplier involved for the Traxium Compressor are based in the French capital and used to make suitcases for fashion giants Louis Vuitton.

Kipsta own the pattern for this process, meaning nobody else can copy. Adidas were working on a similar technology but Kipsta won the race in the market.

.jpg)

They used more than 2000 samples, with a total of 50 different versions of the boots. And as part of the development, they paid 25 players to take part in surveys to get valuable feedback.

They played a 90 minute game, with some playing with laces and others without. The footballers switched at half-time and 80 per cent of people preferred the laceless style which have become increasingly popular in the modern game.

Kipsta also got a Ligue One star onboard in order to ensure the boots were up to scratch. Auxerre left-back Quentin Bernard, without a boots sponsor, has been wearing them for 8 months and deems the footwear to be "one of the best" he's sported.

Testing out the boots on the big 11-a-side pitch at the Kipstadium, they felt extremely comfortable. Fitted to the feet, with grip touch control, high supportive knit collar and scales, passing and crossing felt easier.

1500 pairs are out for release and a new version on the works for 2024, with potential for new colourways.

But a big mission for Kipsta is to change the lifespan of football boots. Typically a pair will last for six months - or 120 uses - but Kipsta want to avoid that and guarantee boots for around 300 uses.

And even then, with no stitches or glue involved, there will be a second life of the product as it the materials are reusable.

With the Traxium Compressor, you're getting high quality boots but for an affordable price.

They might not have the swaz of Nike, Adidas and Puma but I'm going to be tearing it up at Crossley Park playing fields every Sunday wearing them.